In this experiment, four quadrant operation of a DC motor is simulated as well as run in real-time. The speed and current control model developed in the previous experiment is used to emulate the four regions of operation.

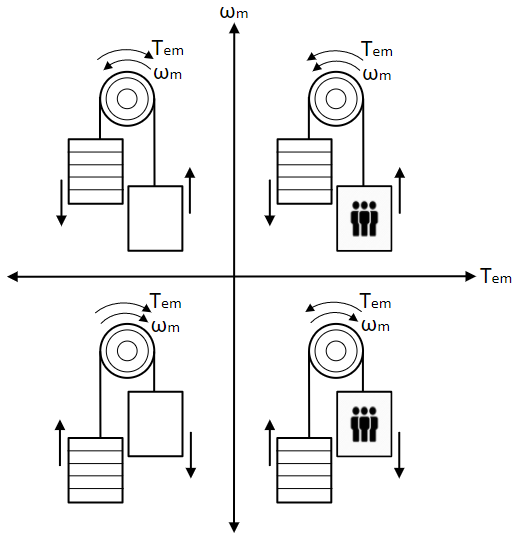

Consider an elevator system shown in figure below. It consists of a carriage, a counter-weight and a pulley driven by a DC motor. The counter-weight is usually set to around 50% of the fully loaded weight of the carriage to maximize overall efficiency.

This system goes through all the 4 quadrants of operation, namely:

Forward Motoring: ωm is positive and Tem is positive

Forward Regeneration/Braking/Generation: ωm is positive and Tem is negative

Reverse Motoring: ωm is negative and Tem is negative

Reverse Regeneration/Braking/Generation: ωm is negative and Tem is positive

Forward motoring occurs when the carriage is loaded more than the counter-weight and the carriage needs to be pulled up, in this case the DC motor must produce torque along the direction of rotation to compensate for the lower counter-weight. Forward regeneration occurs when the carriage is loaded less than the counter-weight and the carriage needs to be pulled up, in this case the DC motor must produce torque against the direction of rotation to prevent the carraige from being drawn too fast by the heavier counter-weight. Reverse motoring occurs when the carriage is loaded less than the counter-weight and the carriage needs to be pulled down, in this case the DC motor must produce torque along the direction of rotation to compensate for the lower weight of carriage. Reverse regeneration occurs when the carriage is loaded more than the counter-weight and the carriage needs to be pulled down, in this case the DC motor must produce torque against the direction of rotation to prevent the carriage from being lowered too fast due to its heavier weight.

In motoring mode power is drawn from the motor and in regeneration mode power is fed back to the motor.

Forward motoring:

Open the speed control simulation model designed in the previous experiment.

Set the reference speed to Step with Final value equals 100 and Step time equals 1.

Set the load torque to Step1 with Final value equals 0.2 and Step time equals 7.

From the Toolbox drag and drop Multiplier Divider tool present in Math Block tool class. Use this multiplier to multiply the motor terminal voltage and the motor current. Add a Scope from Toolbox to observe the result of the multiplication.

Similarly add a multiplier to multiply motor output torque and motor speed and add a scope to observe the result. The motor torque can be obtained by scaling the motor current by kt using a Gain block.

Add a scope to observe the motor output torque.

Run the simulation model and observe the current, speed, output torque, input power and output power.

Forward regeneration: In the model change the Final value of load torque step to -0.2 and re-run the model. Observe all the results as before.

Reverse motoring: In the model change the Final value of reference speed step to -100 and re-run the model. Observe all the results as before.

Reverse regeneration: In the model change the Final value of load torque step to 0.2 and re-run the model. Observe all the results as before.

In the previous section, the motor four quadrant operation was simulated. In this section, the same system is run in real-time.

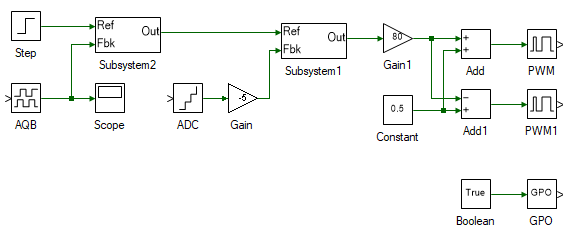

Open the speed control real-time model designed in previous experiment.

Open model properties and set the Step time to 0.0001 and Run time to 10.

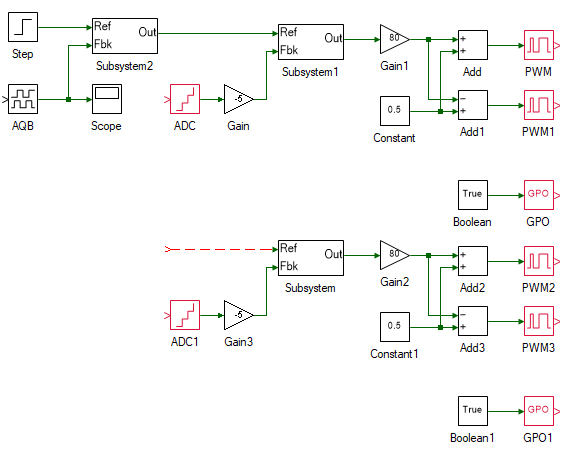

Previously, this system was run in real-time without any load. In this experiment, a torque load is emulated by means of another DC motor coupled to the speed-controlled DC motor. The second motor is run in current control mode, which in turn is torque controlled since torque is merely, kt times motor current. To do this select, copy and paste everything on the right of the speed PI controller as shown:

The newly pasted system is the current-controlled DC motor which will be connected to Inverter 2. The PWM and ADC settings needs to be changed to reflect this.

Change the properties of each tools in the newly pasted system to the values listed in table below.

| Tool name | Property field | Property value | Comments |

|---|---|---|---|

| ADC1 | Channel | 5 | Second motor's current. |

| Gain3 | Gain | 5 | Scaling to convert ADC signal to actual current. The scaling value is given within the ADC property. |

| PWM2 | Channel | 4 | Inverter 2's A-phase leg. |

| PWM3 | Channel | 5 | Inverter 2's B-phase leg. |

| GPO1 | Channel | 2 | Pull inverter 2 out of reset. |

Add a step tool and connect it to the reference input of the PI controller subsystem of the recently pasted system. This step is the reference current. Similar to the simulation, the load torque of the motor is to be stepped to 0.2 Nm. This can be achieved by proportionately stepping the current by 0.2/kt, where kt must be substituted with the value obtained from DC motor characterization experiment. Thus, set the Final value of the step tool to 0.2/kt (substitute value for kt) and the Step time is set to 7.

Add a scope to observe the output current of the motor. In the scope properties, enable data logging.

Connect the motor (the one without the encoder) to Inverter 1 (color of the motor terminal must match that of inverter's). Connect the generator (the one with encoder) to Inverter 2 (once again the color of the motor terminal must match that of the inverter's).

Connect the three-inverter module to the DC power supply. Connect the three-inverter to the computer via USB. Connect the generator speed feedback to the three-inverter's Encoder 1 DSUB connector in the back panel.

Turn ON the DC power supply and set the voltage to 40 V.

Ensure that  button on the top dock, to transition to real-time mode, is pressed. Click the run button.

button on the top dock, to transition to real-time mode, is pressed. Click the run button.

Observe the speed and current result in the scope. Click the  to focus the result. After about 10 s, stop data logging by clicking

to focus the result. After about 10 s, stop data logging by clicking  .

.

Turn OFF the DC power supply.

Similar to simulation, alternate the sign of reference speed and current, and obtain results for all the modes of operation.

Turn OFF the DC power supply and disconnect all the connections including the USB.

This concludes the experiment on DC motor four quadrant operation. In the following experiments AC motors shall be explored.

Attach plot of Ia or Tem, and ωm from simulation and real-time under all modes of operation.

What was the input power and output power for all four modes, after load torque was applied? Is input power greater or less than output power? Explain the results.

Given an elevator with counter-weight of 250 N, pulley of diameter 0.5 m and motor with maximum current of 100 A and torque constant 10, what is the maximum capacity of the carriage?